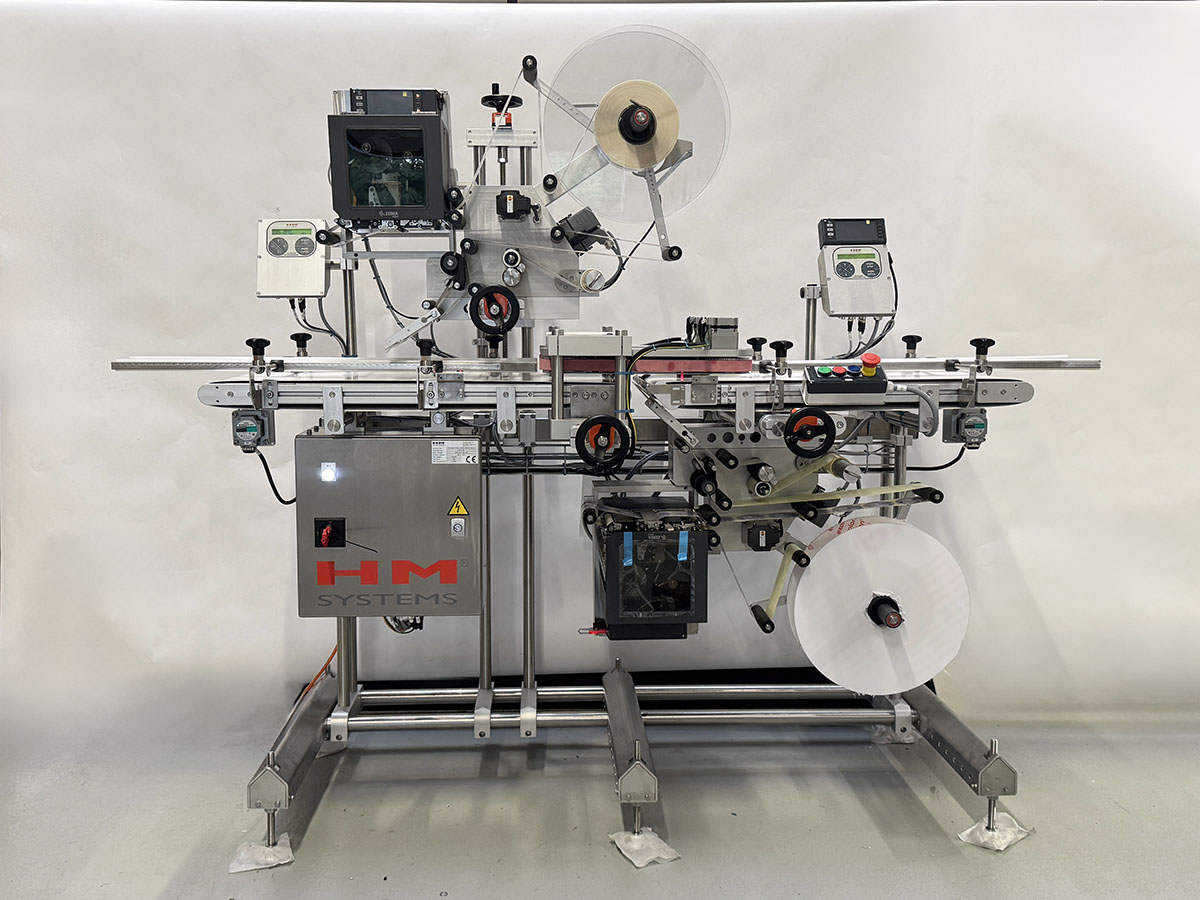

A Dutch food manufacturer has just had a complete top/bottom labelling system installed through our distributor, Contact BV. The system consists of two HM 600P printer dispensers with integrated Zebra print modules.

This system ensures accurate and flexible labelling of cups of various sizes, with precise label positioning and the ability to print variable data such as batch numbers and production dates.

The end customer's goal was to find a solution that could handle multiple product formats on the same line quickly and reliably without compromising on quality.

Previously, this required time-consuming changeovers and posed a risk of inaccurate application.

However, with the new HM 600P solution, operators can now switch between cup formats in a matter of minutes by simply selecting the relevant labelling programme.

The labels are applied with millimetre precision, even when they extend to the very edge of the cup — a crucial requirement for the end customer, for whom the position of the label is also significant in terms of brand identity.

“This machine solves the classic challenge of multiple product formats on the same line,”

explains Jan Kondrup, Sales Manager at HM Systems.

‘When the labels are right up to the edge, there is no room for error. That's why precision has to be top-notch – and the HM 600P delivers that consistently every time.”

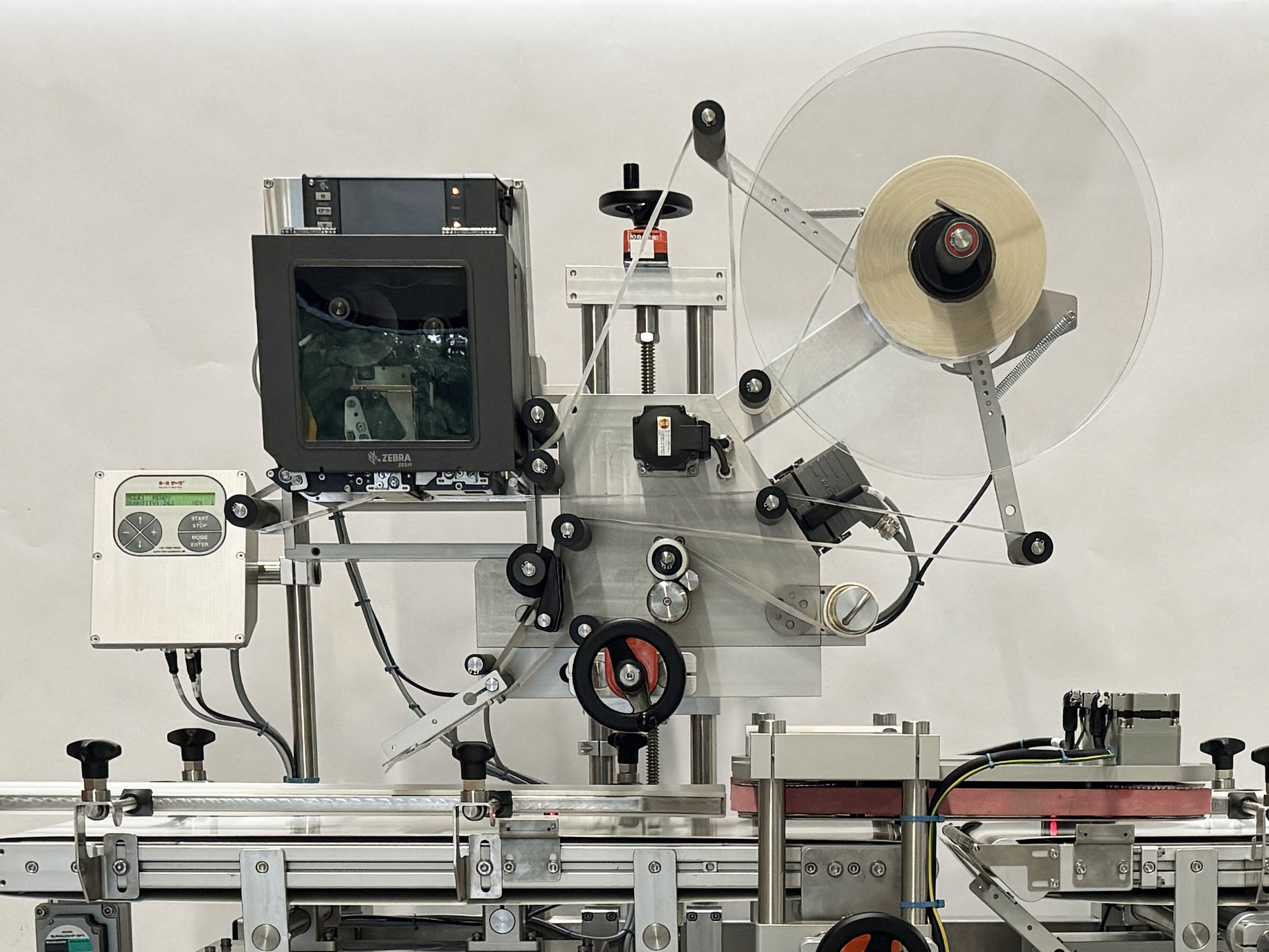

The HM 600P printer dispenser combines labelling and printing in a single, compact unit.

The integrated Zebra printer enables the direct printing of variable data, and the sensor system ensures that labels are always applied precisely to the shape and surface of the product.

“This solution is ideal when customers need both flexibility and consistent labelling,” says Jan Kondrup.

“It provides a more efficient production flow and reliable labelling.”

The machine is equipped with a user-friendly display and can store up to 100 labelling programmes, enabling operators to easily switch between products without adjusting the settings.

This reduces both changeover time and the risk of errors while maintaining high production capacity.

For the end customer, this means production can run with fewer stops and consistent quality, regardless of product variant.

HM Systems' labelling machines are designed for manufacturing companies that require reliable, high-performance machines with a long service life.

Like all HM Systems machines, the HM 600P is made from stainless steel and anodised aluminium. It is developed and tested in Denmark and designed for continuous industrial operation.

With a label width of up to 300 mm and the option to integrate print modules from Zebra, Sato or CAB, as well as advanced sensor systems, HM Systems offers labelling solutions that can be adapted to any production environment, from food production to the pharmaceutical industry.

‘It is precisely the combination of flexibility and precision that makes the HM 600P a strong choice for this type of production,’ concludes Jan Kondrup.

‘The machine can handle different cup sizes on the same production line without compromising on precision.’

Stay up to date on the latest news and innovations on the topic of product marking and labelling.