Custom-built solution with increased stability and IP63 sealing ensures reliable operation under demanding washdown conditions.

From the beginning, the requirements for a major U.S. food producer were clear: the labelling system needed to withstand intensive cleaning and deliver stable, uninterrupted operation.

Our partner Pro-Pac therefore approached us with a request for a customised Cross Web solution that could be built to be more robust than the standard version.

This is due to a production environment where heavy wash-downs, strict hygiene requirements and long operating cycles are part of everyday life. This places high demands on even a robust machine such as the standard HM 4000-Servo Cross Web, which is already designed for 24-hour operation in challenging food processing environments.

The customer required a solution that could withstand frequent, intensive cleaning while maintaining maximum precision in top and bottom labelling on thermoformers.

“Our standard Cross Web is already designed for tough environments, but in this case we needed to enhance both the sealing and the overall stability,” explains Sten Krag-Hansen, CSO at HM Systems.

R&D manager Kenny Bennetsen specified that several key modifications would be required, including:

These upgrades ensure that all potential entry points for water during cleaning are now closed, relocated or fully protected, without affecting the machine’s performance.

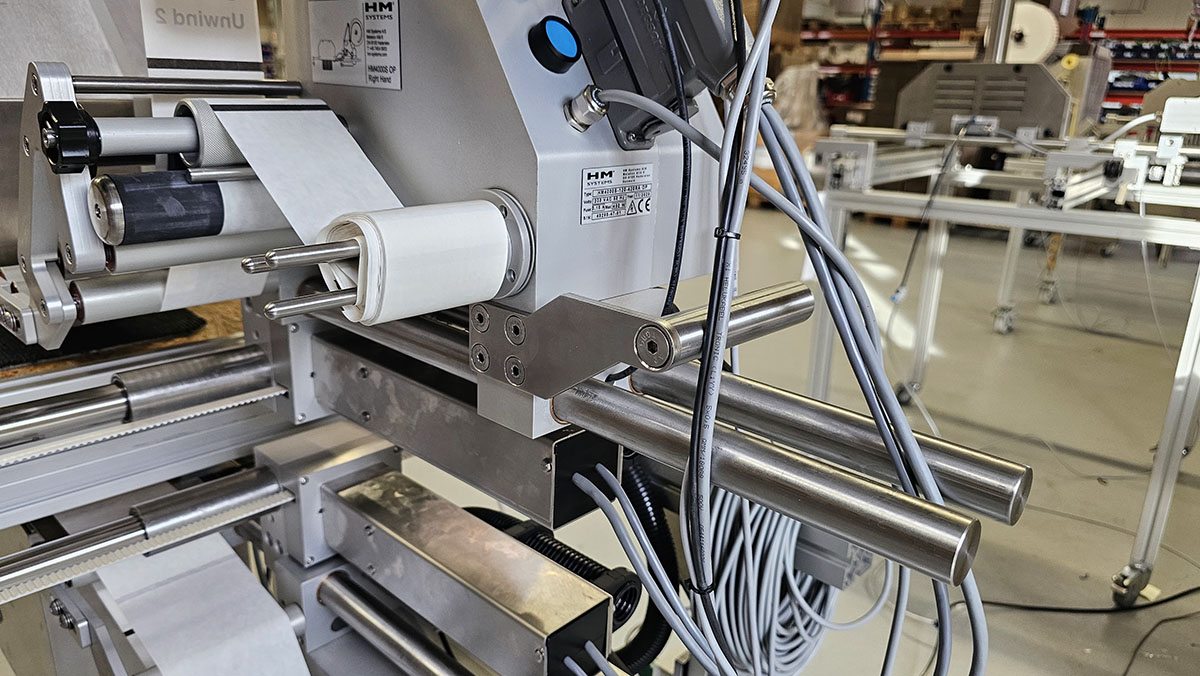

The special Heavy Duty version is built on the foundation of the standard HM 4000-Servo Cross Web.

It delivers the same servo-driven dispensers and labelling speeds of up to 60 m/min as the standard version, as well as a user-friendly control panel with a programme database. However, the construction has been reinforced exactly where the customer’s environment required it.

Customers now have a solution based on a proven platform, with additional robustness where wash-down routines and mechanical load are at their highest.

“The customer needed a robust Cross Web that could ensure stable operation in an environment with frequent and intensive cleaning,” says Sten Krag-Hansen, CSO at HM Systems.

“When production runs around the clock, downtime becomes expensive. That’s why it makes sense to invest in a more stable solution when the production environment demands it.”

Thanks to the mechanical upgrades, the machine now offers better resistance to water, vibration and long-term mechanical strain.

Although the new version is not designed to withstand high-pressure washing from all angles, it provides significantly greater protection against moisture, splashes, and exposure to water than the standard Cross Web.

In practice, this means:

The result is far fewer potential failure points in an environment where moisture would otherwise cause errors, alarms or unnecessary servicing.

Although the solution was developed for one specific food producer, this is a configuration that many across the industry can benefit from.

“This is a great example of how we’re ready to go the extra mile when a producer has special requirements. Once we have developed one customised model, we have the foundation to do it again.” says Sten Krag-Hansen

HM Systems develops both standard equipment and fully customised systems.

If your production environment requires more than a standard setup, or if you have higher demands in terms of sealing, stability or precision, we can help you assess your options.

Stay up to date on the latest news and innovations on the topic of product marking and labelling.