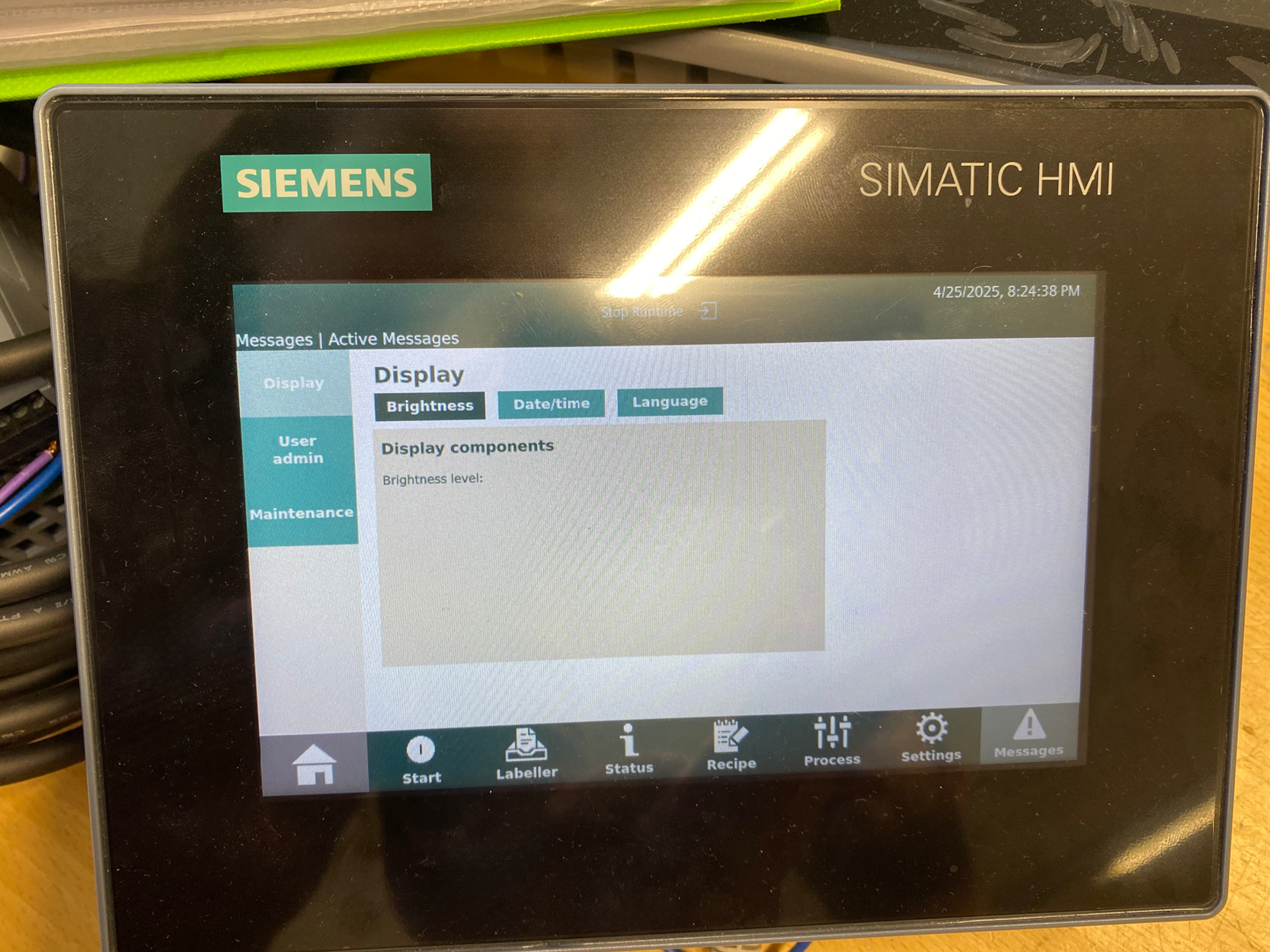

As Siemens phases out its previous screen models, HM Systems has chosen to see this as more than a technical change. It is an opportunity to strengthen both our visual identity and the user experience on the machines we deliver to customers around the world.

To seize that opportunity, we have completed a cross-functional project where skills from both engineering and marketing were brought together to create a completely new UX design for our machine displays.

The project has been driven jointly by Michael Lindegaard from the electrical department, who works as a PLC programmer and technician, and Patricia L. A. Jensen from marketing, who is a marketing assistant with a background as a web integrator and multimedia designer.

Both perspectives have been equally important:

Michael’s technical view on functionality, logic and the possibilities in the system

Patricia’s communicative and visual view on structure, clarity and design

“We’ve been able to make it simpler and easier for users to navigate the system in their busy everyday lives,” explains Michael.

“By looking closely at how operators actually work at the machine, we’ve cleaned up unnecessary elements and made functions more logical and accessible.”

Patricia adds:

“Our focus has been on making the interface visually clear and user-friendly. We’ve used card sorting, talked through each menu point and function, and aligned colours and layouts with HM Systems’ design guide. Along the way, we have iterated on prototypes, tested and adjusted until it both looked right and felt right for users.”

By combining these two viewpoints, we have ensured that the new design both works in practice at the machine and feels more intuitive and recognisable for users.

The new UX design has been developed using design thinking as the overall approach. This means the process has been iterative, exploratory and user-focused rather than a one-off redesign of the screens.

Along the way, we have:

mapped the user journey and identified the most important work situations at the machine

carried out card sorting and structured dialogue about each menu point and function

removed elements that no longer made sense or added value

created a clearer structure in the navigation, making it easier to find the right place

developed prototypes, tested them and continuously refined both design and content

The goal throughout has been that every menu option has a clear purpose, and that users are never in doubt about what their next step should be.

The project has also been an opportunity to create an even stronger visual red thread across HM Systems’ solutions.

The new interface has been designed in HM Systems’ colours, with updated icons and screen layouts that follow our design guide. This provides a more professional and recognisable expression, no matter which machine you're standing at.

For the user, this means:

a calmer and more coherent visual environment

improved readability and clearer prioritisation of information

easier recognition across different machines and screen types

The new UX design is now ready to be used, and the first machine with the new interface will be shipped next week. Going forward, this design will become our new standard for HM Systems’ screens.

The new screens also offer important technical advantages:

we can update and roll out changes remotely

we can support customers more easily by monitoring what is happening in the machine

we can analyse and resolve issues more quickly, without always needing to be on site

The result is a more intuitive and coherent interface that follows our design guide, makes it easier for operators and technicians to work with the machines, and allows us to roll out updates and improvements remotely to support customers faster and troubleshoot directly via the machine’s data.

Because Siemens is now phasing out the old screen models, the new UX design will be introduced on new machines that are built with the new screens from now on.

This means that:

customers who order new machines with the new Siemens screens will receive the updated design as standard

existing machines with the previous screen generation will continue to run with their current interface

In other words, the change affects new deliveries going forward, while existing installations remain unchanged.

Stay up to date on the latest news and innovations on the topic of product marking and labelling.