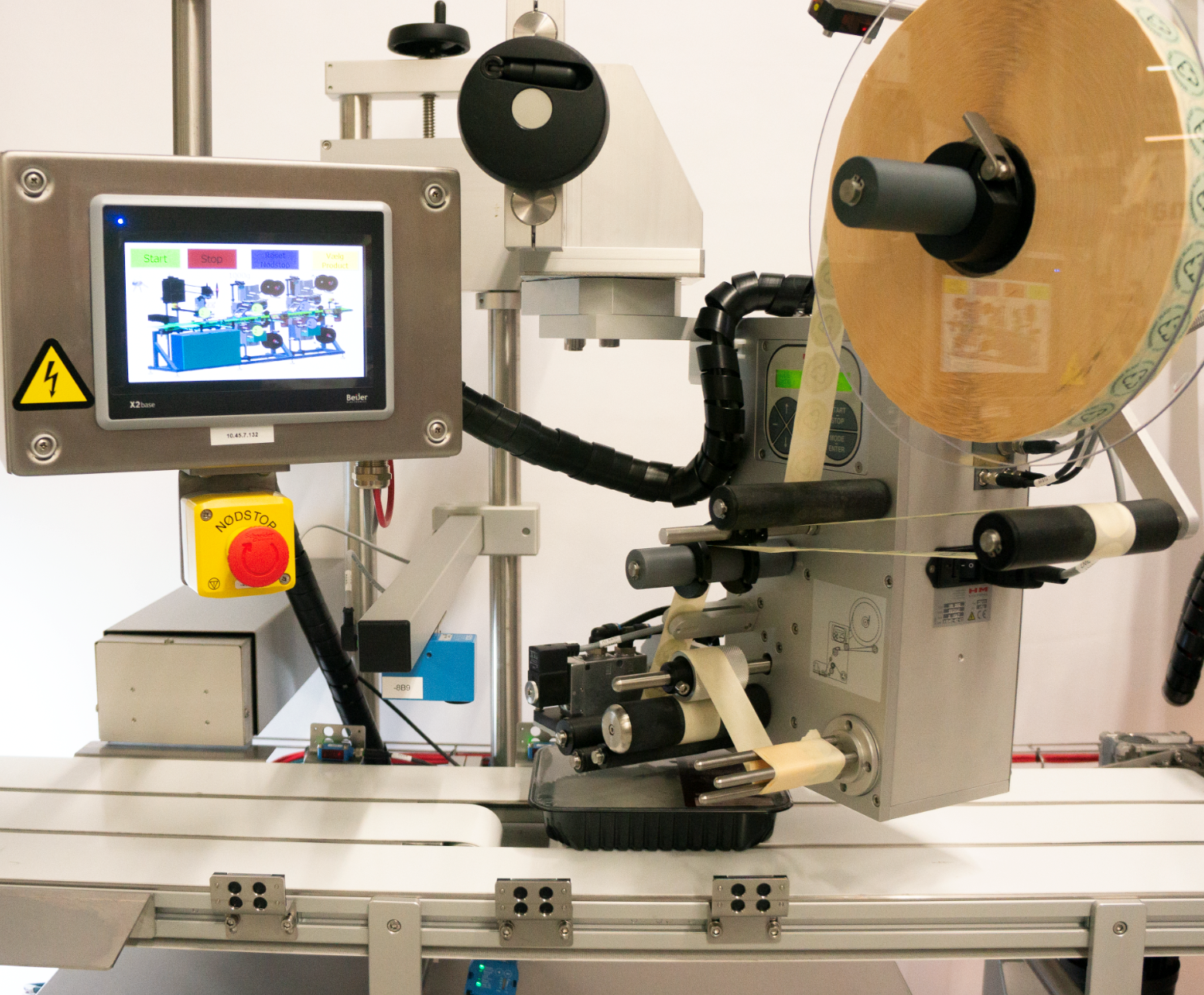

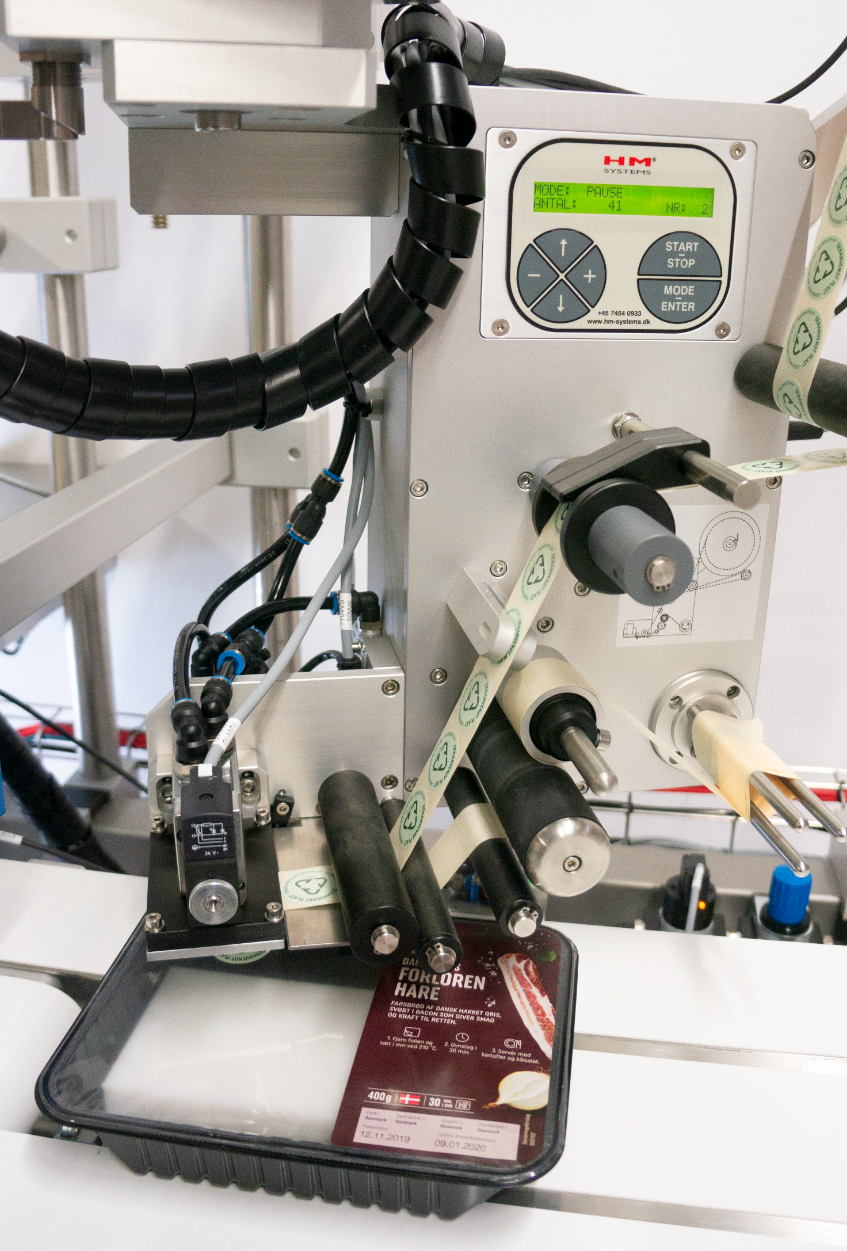

Top & bottom labelling system with label control These new systems have been designed for 24-hour non-stop operation to achieve the highest possible efficiency and uptime. The automatic labelling system features two top and two bottom labelling heads with print engines as well as a campaign flash labeller. To secure continuous operation the systems have been designed in such a way that the second machine will automatically take over when the first machine runs out of labels. The system is operated via a touch panel containing all recipes used. Efficient print of labels via industrial print engines Both top and bottom label heads are equipped with robust industrial print engines, which are able to print and apply barcodes, best-before-dates and ingredient information. Flash labels for special campaigns Additionally, the system is able to apply a flash label to the product to be used for campaigns with special prices or special product information. Flash labels are typically round labels with special price information, which are blown to the top of the products. The labels can be placed in many different positions via a flexible positioning system.

Verification of labels applied through automatic label control All labels and barcodes are checked on a continuous basis via a scanner and a PLC. A barcode placed on the backing paper must be identical on both top and bottom labels in order for production to run. If labels are missing or data is incorrect, the products are rejected to a manual rework station. This ensures that only correctly labels are used at all times and the risk of product withdrawal is eliminated.